charpy impact test subsize|charpy impact test calculator : supermarket NIST in Boulder Colorado investigated the correlations between impact test results obtained from standard, full-size Charpy specimens (CVN) and specimens with reduced thickness (sub-size . The answer lies within: choose carefully! Experience the thrill of The Lucky Jet Game – a high-powered adventure full of adrenaline and excitement! Find out what awaits you in .

{plog:ftitle_list}

We enjoyed testing the Fugitive Gold online slot and have no trouble recommending it as a fun addition to the High 5 Games catalog. This highly volatile game has 96.00% RTP and 243 ways to win. Spin with wilds in the base game and get to the free spins round for expanding wilds and higher odds of . Ver mais

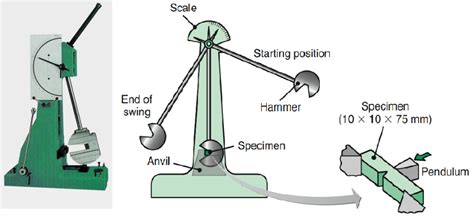

The normal standard size for a Charpy impact test specimen is a 10mm by 10mm by 55mm long specimen for ISO 148 and ASTM E23/ASTM A370 standards. However, not all test pieces allow for the standard size to be .Wallin K Upper shelf energy normalisation for sub-sized Charpy-V specimens. Int J of Pressure Vessels and Piping, 78, 2001, pp 463-470. Sub-size specimens yield lower proportional upper .NIST in Boulder Colorado investigated the correlations between impact test results obtained from standard, full-size Charpy specimens (CVN) and specimens with reduced thickness (sub-size .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .

Overview of NIST Activities on Subsize and Miniaturized Charpy Specimens: Correlations With Full-Size Specimens and Verification Specimens for Small-Scale Pendulum .4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications 5 Information to be gained from the impact test 6 Subsize test pieces

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .Evaluation methodology of standard Charpy impact properties in the cleavage fracture region from subsized specimen test results has been demonstrated. It consists of 1) subsized Charpy .Full-size, half-size, and third-size specimens from several different steels have been tested as part of an ongoing alloy development program. The smaller specimens permit more . Subsize specimens in Charpy impact tests has are a valuable substitute to predict the ductile-to-brittle transition temperature (DBTT) and the upper shelf energy (USE) .

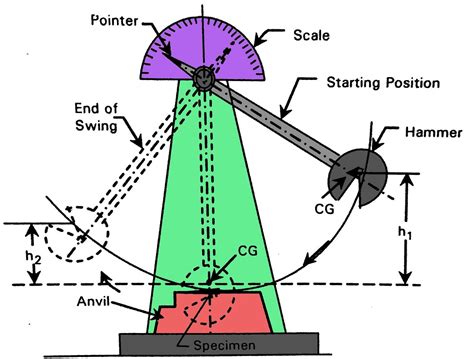

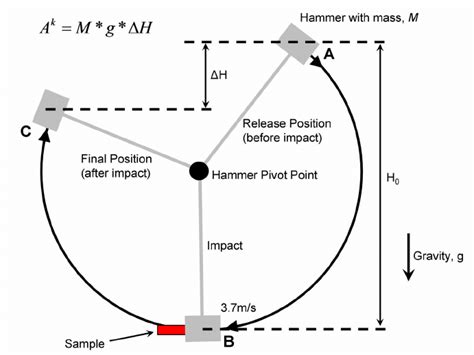

The impact test specimen width is only 5mm (71% of the material thickness) and Table 6 specifies a temperature reduction of 11°C. The actual reduction in test temperature below the standard test temperature for this situation is the difference .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .Converting to specific energy enabled comparisons to be made between the standard and subsize geometries; various studies have been conducted investigating size effects in Charpy testing [20, 21 .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

charpy impact test sample

charpy impact test procedure

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The Charpy impact test has been simulated based on the determined parameters combined with the trial algorithm method. According to the test results, the strain rate related damage parameter was deduced and the reliabilities of the FEM results were verified. Finally, based on the constitutive parameters and damage parameters of J-C model .

Small Punch test (SPT), Micro-Tensile test (M-TT) and instrumented mini-Charpy impact test are employed here. The SPT method uses a small disk-shaped testing sample of usual dimension of 8 mm in .

Subsize specimens in Charpy impact tests has are a valuable substitute to predict the ductile-to-brittle transition temperature (DBTT) and the upper shelf energy (USE) anticipated for full size . Using subsize Charpy V-notch-type specimens requires the establishment of a specimen geometry that is adequate to obtain a ductile-to-brittle transition curve similar to that obtained from full-size specimens, and the development of correlations for transition temperature and upper-shelf energy (USE) level between subsize and full-size specimens. This table is for subsize CVN specimens regardless of welding process. Second, for subsize Charpy impact specimens, the test temperature must be reduced in accordance with Table 323.3.4 because of geometry affects - thinner specimens will exhibit higher impact energy values because of less constraint from reduced thickness.

The ductile to brittle transition with decreasing temperature has been investigated by Charpy impact test with sub-size specimen for the ferrite + pearlite structure steel sheet. The transition . The potential for using subsize specimens to determine the actual properties of reactor pressure vessel steels is receiving increasing attention for improved vessel condition monitoring that could be beneficial for light-water reactor plant-life extension. This potential is made conditional upon, on the one hand, by the possibility of cutting samples of small volume .The instrumented impact test with Charpy specimens of subsize geometry is discussed in relation to equivalent standard procedures for performing the test with specimens of regular size. Subsize specimens because of their smaller dimensions imply smaller load values and higher frequencies of the force oscillations.

The requirement to reduce the test temperature for sub-size impact test specimens is compensate for the fact, that thinner test specimens tend to have better impact test properties. To quote Peng & Peng's 'Pipe Stress Engineering', page 12: 'This thickness correlation is mainly because a thicker wall creates a higher uneven stress distribution . D. François, A. Pineau (Eds.), From Charpy to Present Impact Testing, ESIS Publication 30, Elsevier (2002), pp. 57-68. View PDF View article View in Scopus Google Scholar [2] R. McNicol. Correlation of Charpy test results for standard and nonstandard size specimens. Weld. J. Res. Suppl. (1965), pp. 385-393. Furthermore, the Charpy impact test results are affected by many factors, and scholars have conducted many studies in this area. Madhusudhan and Cao studied the effect of several different striker velocities .

Effects of V-Notch Dimensions on Charpy Impact Test Results for Differently Sized Miniature Specimens of Ferritic Steel,” Mater. Trans. JIM, 34, 1993, pp. 1042–1052. 3. Sokolov, M. A. and . Nanstad, R. K., “ On Impact Testing of Subsize Charpy V-Notch Type Specimens,” Effects of Radiation on Materials: 17th International Symposium, ASTM .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Section VIII. This is the only article found that links ASME UG-84.2 to Charpy impact properties. A review of other code requirements with provisions for subsize Charpy specimens may be useful for comparison to A370/Table 9. The adequacy of code requirements for sub-sized Charpy testing was reviewed by Towers in 1986 (Towers, 1986).6 Subsize test pieces. 7 Recommendations for specifying impact strength requirements in steel specifications. . 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces.

Testing of subsize specimens manufactured from broken halves of previously tested surveillance Charpy V-notch (CVN) specimens offers an attractive means of extending existing surveillance programs. Using subsize CVN type specimens requires the establishment of a specimen geometry that is adequate to obtain a ductile-to-brittle transition curve .

Sat Dec 31 00:00:00 EST 1994 ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum. In addition, plant life extension will require supplemental data that cannot be provided by existing surveillance programs. Testing of subsize specimens manufactured from broken halves of previously tested surveillance Charpy specimens offers an attractive means of extending existing surveillance programs. The instrumented impact test with Charpy specimens of subsize geometry is discussed in relation to equivalent standard procedures for performing the test with specimens of regular size. Subsize specimens because of their smaller dimensions imply smaller load values and higher frequencies of the force oscillations.

Abstract In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens (4340 quenched and tempered with two energy levels, and T200 18Ni maraging steel).

charpy impact test pdf

rubber in a can spray drop test

Gostaríamos de exibir a descriçãoaqui, mas o site que você .

charpy impact test subsize|charpy impact test calculator